WILDCARD WEEK

Concept

This being a wild week means basically anything crazy goes on whatever one csm produce giving a basic produral way of how one went about it. Therefore being a pendemic worldwide I was thinking of a way to communicate to people having no ability to see of what is going on around the world, Not only for the situation that is going on but how can we be able to communicate major details of objects an item for example being purchased or details of an object having a history into it, how do we pass to these small details to people first hand without involving a third party person

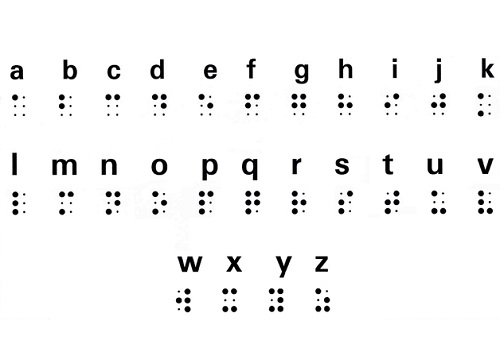

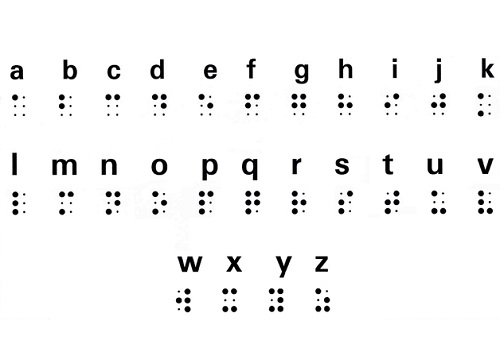

I decided to use the technology of 3D printing and sense of touch to try do a defference big or small. I decided to first dig deep into research to who and how other people are deeping themselves in this field During my research i came across friends who had the the idea before me and i got to talk to them to gain knowledge about how the fiels is and see what they do.

During the research i came across several problems that could be tackled in this field this includes the following:

Design

After some research i decided to dig in the work and see if i can produce something I decided to go with following:

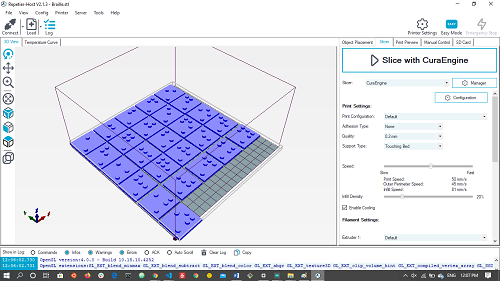

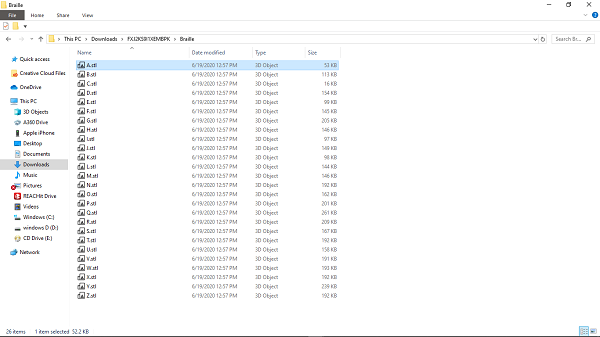

There alot of designs that are online and i decided to take advantage of it to move forward. I used some of the designs found in Grabcad as well as thingiverse to see if i would make sense of the idea of communicating snd to see if i can solve one of the problems found during research which is lack of brailles to teach and educate. i printed the models using my printers, though i knew it will take longer to test this due to the situation going on worldwide.

the design files can be found on the link below

design fileThis would make it easier for any person wanting to learn the braille

I went right ahead to tring and solve something to do with social barrier and this included ways of making it easier for this person blend in the society by making them feel normal making them feeling independent. With this i decided to the following be asking myself the following:

To kick this off i went on to try different way i could do this:

This was the first trial to see if things it would work out for blind and the impered people i decided to use copper since of its thickness and regidity. this part of the experiment was not successful so i decided to hold back and go to the drawing board for the same

Moving on i decided to try printing braille on clothes like how you would print a logo or a message on shirt this was a new experiment and the worry was if it would stick on material clothing

from the research i found my friend done more in this and i wanted to know what the were doing doing and i decided to partner with to see what we can do

together.

some of her work you can find in the video interview i will share the link at the end of this.

from the research i found my friend done more in this and i wanted to know what the were doing doing and i decided to partner with to see what we can do

together.

some of her work you can find in the video interview i will share the link at the end of this.

trials and challenges

cutting went wrong

this was the most difficult part to do especially when it comes to sticking to clothing it was difficult

for vinyl cutting it turned out the dotts were to small to be lifted off from the initial paper and also during cutting the vynyl machine will end up doinf a mess of the paper.

i Decided to just forcus on the printing

Being a thing that i wanted to do and help i decided to take my time in doing research and gaining more data in the field before moving forward.

here is a link to Hisi studio interview Angie Wangiku main interview.